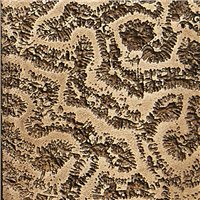

Jesmonite Flex Metal Gel Coats are the latest development in Jesmonite materials. Jesmonite Flex Metal Gel Coats are formulated to produce metal finishes which are both decorative and durable. They are available in four finishes: Bronze, Copper, Brass, and Silver Bronze. They are used in combination with AC730 or AC830 as a backing material mixed with either Flex or standard liquids dependent upon the type of object being manufactured.

Information

- Utilises our unique Flex Resin technology to create the first and only water based metallic gel coat system.

- Metals can be infinitely mixed and pigmented to further expand the palette of finishes.

- Ex-mould surfaces can be polished with fine grades of wire wool to reveal the metal powders by hand or polishing machinery can be used with our metallic polishing heads.

- Metallic surfaces can be waxed, sealed or have a patina applied just like real metal.

It is essential to use both accurate scales and a Jesmonite High-shear Mixing Blade to ensure that the compound performs within its specification. Failure to follow these instructions can lead to strength loss, shrinkage, and reduced durability. Workshop conditions should be warm, dry, and out of direct sunlight. Environments where solvent-based compounds are in regular use should be avoided. Mixing containers should be clean and dry, and of a suitable size. Flex Metal Gel Coats will work best using Silicon Rubber moulds, however it is also possible to use Polyurethane moulding compounds with an appropriate spray release wax. Rigid GRP, wooden, plaster moulds are best avoided.

Weigh the Liquids and Base into separate clean containers at the following ratio:

AC730FM Liquids 1 part by weight

AC730FM Bronze Base 5.5 parts by weight

AC730FM Liquids 1 part by weight

AC730FM Brass Base 5.5 parts by weight

AC730FM Liquids 1 part by weight

AC730FM Copper Base 7 parts by weight

AC730FM Liquids 1 part by weight

AC730FM Silver Bronze Base 6 parts by weight

In general, the mixture can be adjusted to suit the application or the needs of the end user. Adding a little Liquid or Base to make fine adjustments is very useful – do small batch trials first to assess the materials suitability to a particular mould or application. The mix should be thick, but easy to apply by brush at 1mm – 2mm thickness.

Jesmonite Flex Metal Gel Coats must be mixed using a High-shear Mixing Blade. Attach this blade to a drill with variable speed control on the trigger and slowly add the Base to the Liquids whilst mixing continuously at low speed. As the last powders are added, slowly increase the mix speed to around 1,000rpm and mix for a further 60 seconds or until the mix is smooth, flowing and free from lumps. It is very important to keep the mix stirred whilst applying to stop any settlement of the heavy metal powders contained within the material.

Be the first to review this product